Product Description

Couplings Fluid Flange Flexible HRC Chain Fenaflex Spacer PIN MH Rigid NM Jaw Gear transmission industrial gearbox manufacture parts pric F Flexible Coupling

YOXz is a coincidence machine with moving wheel which is in the output point of the coincidence machine and is connected with elastic axle connecting machine (plum CZPT type elastic axle connecting machine or elastic pillar axle-connecting machine or even the axle-connecting machine designated by customers). Usually there are 3 connection types.

YOXz is inner wheel driver which has tight structure and the smallest axle size.The fittings of YOXz have a wide usage, simple structure and the size of it has basically be unified in the trade.The connection style of YOXz is that the axle size of it is longer but it is unnecessary to move the electromotive machine and decelerating machine. Only demolish the weak pillar and connected spiral bolt can unload the coincidence machine so it is extreme convenient. Customer must offer the size of electromotive machine axle (d1 L1) and decelerating machine axle (d2 L2). The wheel size (Dz Lz C) in the table is just for reference, the actual size is decided by customers.

Main Features

1. Applies to flexible drive shaft ,allowing a larger axial radial displacement and displacement.

2.Has a simple structure,easy maintenance .

3.Disassembly easy

4.low noise

5.Transmission efficiency loss,long useful working life.

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | – |

| Torque: | – |

| Bore Diameter: | – |

| Speed: | – |

| Structure: | Flexible |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

What Is a Coupling?

A coupling is a device used to connect two shafts. It transmits power between them and allows for some misalignment or end movement. There are several types of couplings. The most common ones are gear couplings and planetary couplings. However, there are many others as well.

Transfer of energy

Energy coupling is a process by which two biological reactions are linked by sharing energy. The energy released during one reaction can be used to drive the second. It is a very useful mechanism that synchronizes two biological systems. All cells have two types of reactions, exergonic and endergonic, and they are connected through energy coupling.

This process is important for a number of reasons. The first is that it allows the exchange of electrons and their energy. In a single molecule, this energy transfer involves the exchange of two electrons of different energy and spin. This exchange occurs because of the overlap interaction of two MOs.

Secondly, it is possible to achieve quadratic coupling. This is a phenomenon that occurs in circular membrane resonators when the system is statically deflected. This phenomenon has been gaining a great deal of interest as a mechanism for stronger coupling. If this mechanism is employed in a physical system, energy can be transferred on a nanometer scale.

The magnetic field is another important factor that affects the exchange of energy between semiconductor QWs. A strong magnetic field controls the strength of the coupling and the energy order of the exciton. The magnetic field can also influence the direction of polariton-mediated energy transfer. This mechanism is very promising for controlling the routing of excitation in a semiconductor.

Functions

Couplings play a variety of functions, including transferring power, compensating for misalignment, and absorbing shock. These functions depend on the type of shaft being coupled. There are four basic types: angular, parallel, and symmetrical. In many cases, coupling is necessary to accommodate misalignment.

Couplings are mechanical devices that join two rotating pieces of equipment. They are used to transfer power and allow for a small degree of end-to-end misalignment. This allows them to be used in many different applications, such as the transmission from the gearbox to the differential in an automobile. In addition, couplings can be used to transfer power to spindles.

Types

There are two main types of couplings: rigid and flexible. Rigid couplings are designed to prevent relative motion between the two shafts and are suitable for applications where precise alignment is required. However, high stresses in the case of significant misalignment can cause early failure of the coupling. Flexible couplings, on the other hand, allow for misalignment and allow for torque transmission.

A software application may exhibit different types of coupling. The first type involves the use of data. This means that one module may use data from another module for its operation. A good example of data coupling is the inheritance of an object. In a software application, one module can use another module’s data and parameters.

Another type of coupling is a rigid sleeve coupling. This type of coupling has a pipe with a bore that is finished to a specified tolerance. The pipe contains two threaded holes for transmitting torque. The sleeve is secured by a gib head key. This type of coupling may be used in applications where a couple of shafts are close together.

Other types of coupling include common and external. Common coupling occurs when two modules share global data and communication protocols. This type of coupling can lead to uncontrollable error propagation and unforeseen side effects when changes are made to the system. External coupling, on the other hand, involves two modules sharing an external device interface or communication protocol. Both types of coupling involve a shared code structure and depend on the external modules or hardware.

Mechanical couplings are essential in power transmission. They connect rotating shafts and can either be rigid or flexible, depending on the accuracy required. These couplings are used in pumps, compressors, motors, and generators to transmit power and torque. In addition to transferring power, couplings can also prevent torque overload.

Applications

Different coupling styles are ideal for different applications, and they have different characteristics that influence the coupling’s reliability during operation. These characteristics include stiffness, misalignment capability, ease of installation and maintenance, inherent balance, and speed capability. Selecting the right coupling style for a particular application is essential to minimize performance problems and maximize utility.

It is important to know the requirements for the coupling you choose before you start shopping. A proper selection process takes into account several design criteria, including torque and rpm, acoustic signals, and environmental factors. Once you’ve identified these parameters, you can select the best coupling for the job.

A gear coupling provides a mechanical connection between two rotating shafts. These couplings use gear mesh to transmit torque and power between two shafts. They’re typically used on large industrial machines, but they can also be used in smaller motion control systems. In smaller systems, a zero-backlash coupling design is ideal.

Another type of coupling is the flange coupling. These are easy to manufacture. Their design is similar to a sleeve coupling. But unlike a sleeve coupling, a flange coupling features a keyway on one side and two threaded holes on the other. These couplings are used in medium-duty industrial applications.

Besides being useful for power transmission, couplings can also prevent machine vibration. If vibration occurs in a machine, it can cause it to deviate from its predetermined position, or damage the motor. Couplings, however, help prevent this by absorbing the vibration and shock and preventing damage to expensive parts.

Couplings are heavily used in the industrial machinery and electrical industries. They provide the necessary rotation mechanism required by machinery and other equipment. Coupling suppliers can help customers find the right coupling for a specific application.

Criteria for selecting a coupling

When selecting a coupling for a specific application, there are a number of different factors to consider. These factors vary greatly, as do operating conditions, so selecting the best coupling for your system can be challenging. Some of these factors include horsepower, torque, and speed. You also need to consider the size of the shafts and the geometry of the equipment. Space restrictions and maintenance and installation requirements should also be taken into account. Other considerations can be specific to your system, such as the need for reversing.

First, determine what size coupling you need. The coupling’s size should be able to handle the torque required by the application. In addition, determine the interface connection, such as straight or tapered keyed shafts. Some couplings also feature integral flange connections.

During the specification process, be sure to specify which materials the coupling will be made of. This is important because the material will dictate most of its performance characteristics. Most couplings are made of stainless steel or aluminum, but you can also find ones made of Delrin, titanium, or other engineering-grade materials.

One of the most important factors to consider when selecting a coupling is its torque capability. If the torque rating is not adequate, the coupling can be damaged or break easily. Torque is a major factor in coupling selection, but it is often underestimated. In order to ensure maximum coupling performance, you should also take into consideration the size of the shafts and hubs.

In some cases, a coupling will need lubrication throughout its lifecycle. It may need to be lubricated every six months or even once a year. But there are couplings available that require no lubrication at all. An RBI flexible coupling by CZPT is one such example. Using a coupling of this kind can immediately cut down your total cost of ownership.

editor by CX 2023-06-14

Planetary made in China – replacement parts – in Pretoria South Africa Planet Gear Grinding Tooth Process Spur Gear for Gearbox with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 distinct branches. For a lot more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

| HangZhou helix spur ring pinion sunshine gear wheel |

| With carton box outdoors, plastic luggage inside of with carton board individual every single other |

| forty five-60 times right after payment |

As a membership of HangZhou substantial accurate gears enterprises, HangZhou HangZhou EPT EPT Co., Ltd. is specialized in planning, manufacturing and promoting all types of hard & soft toothed gears, started in 2004 and found in Zhangzhuang industrial park. With much more than a hundred and fifty employees and masking an area over 16000 sq. meters, the yearly production of company can attain in excess of two million parts gears, mo EPT utilized in auto oil pump, motorcar, reducer, and equipment box. The company was awarded as ZheJiang Province Large Technologies company, and business honoring contracts and standing by track record. A Grade taxpaying organization and an enterprise of AAA credit history grade.

We have different te EPT machines and equipped above two hundred sets lathes, including all sorts of hobbing machines, grinding machines, shaping devices, shaving machines and so on. The gears with manufacturer “HangZhou” handed ISO9001: 2000 top quality method in 2008. We have a lot of famous clients in domestic and abroad, such as Brevini from Italy, FAW Fuao company, HangZhou Jinling Intenal-Combustion Engine Fittings Co., Ltd., HangZhou Qingqi Team, ZHangZhoug Buyang Group and so on.

HangZhou inherits the organization philosophy of “good faith, passion, aspiration and motion”, completely utilizes methods superiority, constantly pioneers and invents, absorbs hi-tech talents, introduces superior creation & inspection tools and management methods and constantly improves quality of HangZhou regarding technological innovation, generation, good quality and revenue and so on., in addition, the firm constantly remains core aggressive power in the market place.

The use of authentic products manufacturer’s (OEM) portion numbers or trademarks , e.g. CASE® and John Deere® are for reference reasons only and for indicating item use and compatibility. Our organization and the outlined alternative components contained herein are not sponsored, approved, or produced by the OEM.

Custom made in China – replacement parts – in Thiruvananthapuram India 36mm Planetary Gearbox with Low Speed Brush DC Electric Gear Motor with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing facility in China with 5 diverse branches. For more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Description:

Merchandise Name : 36mm Velocity reducer, planetary geared motor

Gearbox Variety: Planetary gears

Substance: Powder metallurgy Metal

Equipment Ratio : 5:1 , 10:1 , twenty:1 , 25:1 , 30:1 , 40:1 , fifty:1 , sixty:1 ,70:1…100:1… customised

Gearbox diameter : 6mm , 8mm,10mm , 12mm , 16mm , 22mm , 24mm , 32mm , 38mm , 42mm ……

3V , 12V ,24V obtainable .

Torque: 20 – 50 Nm, 10 – twenty Nm, 5 – 10 Nm,1 – 5 Nm, .5 – 1 Nm, .2 – .5 Nm, – .1 Nm, .1 – .2 Nm

D Shaft :4mm stainless metal output shaft

Color : Black & silver

RPM : 10, 20 , 30 , forty , fifty ,sixty

We are a manufacturing facility specialised in metal gearbox by way of powder metallurgy approach & metallic injection molding MIM procedure and dc motor .We services with ODM/OEM gear motor design and style and growth , an expecienced gearmotors producer.

A planetary (or epicyclical) gearbox uses epicyclical gears for pace reduction. It is composed of a single or more toothed whee EPT turning all around a rotating shaft. Each and every rotates on its possess axis as properly as revolving all around the central shaft. This supplies wonderful reduction functionality in a tiny place, making them typical in automated transmissions.These mechanisms are used anywhere effectiveness and higher reduction ratios are necessary in a tiny area. Examples are automatic transmissions and several industrial purposes employing electrical gear motors.

planetary gears also refer as epicyclic gearing consisting three aspects sun gear, planet equipment and ring equipment. Sunshine equipment is positioned at the centre that transmits torque to earth gears orbiting all around the solar equipment. The two programs are found inside the ring gear. In the toothed development sunshine and planet gears are externally mesh and ring equipment internally meshes.

Planetary equipment is located in numerous variation and arrangements to meet up with a broad selection of pace-ratio in the deign requirements. Planetary gear method is use in may differ purposes such as, clocks, lunar calendar, automobile mirror, toys, gearhead motor, turbine engine and numerous a lot more.

Planetary Gearbox benefits:

- Coaxial arrangement of input shaft and output shaft

- Load distribution to several planetary gears

- High performance due to low rolling power

- Almo EPT unrestricted transmission ratio options because of to combination of several world levels

- Appropriate as planetary switching equipment owing to fixing this or that component of the gearbox

- Chance of use as overriding gearbox

- Favorable volume output

- Suitability for a wide assortment of application

Application :

- Health-related and Wellness Business

- Electronics and Telecommunication Business

- Robotics Industry

- EPT Industry

- CNC, Machine, and Resource EPT Industries

- Vehicle, Textile, Printing, Meals, and Metallurgical Industries

Equipment motors for Household application :electric powered shaver, tooth brush, kitchen area appliances, hair clipper, stitching equipment, massager, vibrator, hair dryer, rubdown device, corn popper, scissor hair equipment, vacuum cleaner, garden resource, sanitary ware, window curtain, espresso equipment, whisk, clever closestool, Sweeping robotic and and many others.

For Automotive merchandise :conditioning damper actuator, door lock actuator, retractable rearview mirror, meters, optic axis management gadget, head mild beam degree adjuster, auto h2o pump, automobile antenna, lumbar support, EPB,Car tail gate electric putter,electricity liftgate and so forth.

For Office automation gear:OA products, scanners, printers, multifunction equipment duplicate machines, fax, FAX paper cutter, personal computer peripheral, financial institution device, Video clip convention etc.

For Toys and types:radio control design, automated cruise management, ride-on toy and so on.

Geared motors for computerized gadget .

Customized 36mm small geared motors , planet gearhead , steel gearbox , module gear motor system

Workshop

The use of original tools manufacturer’s (OEM) portion quantities or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating solution use and compatibility. Our firm and the detailed replacement components contained herein are not sponsored, approved, or created by the OEM.

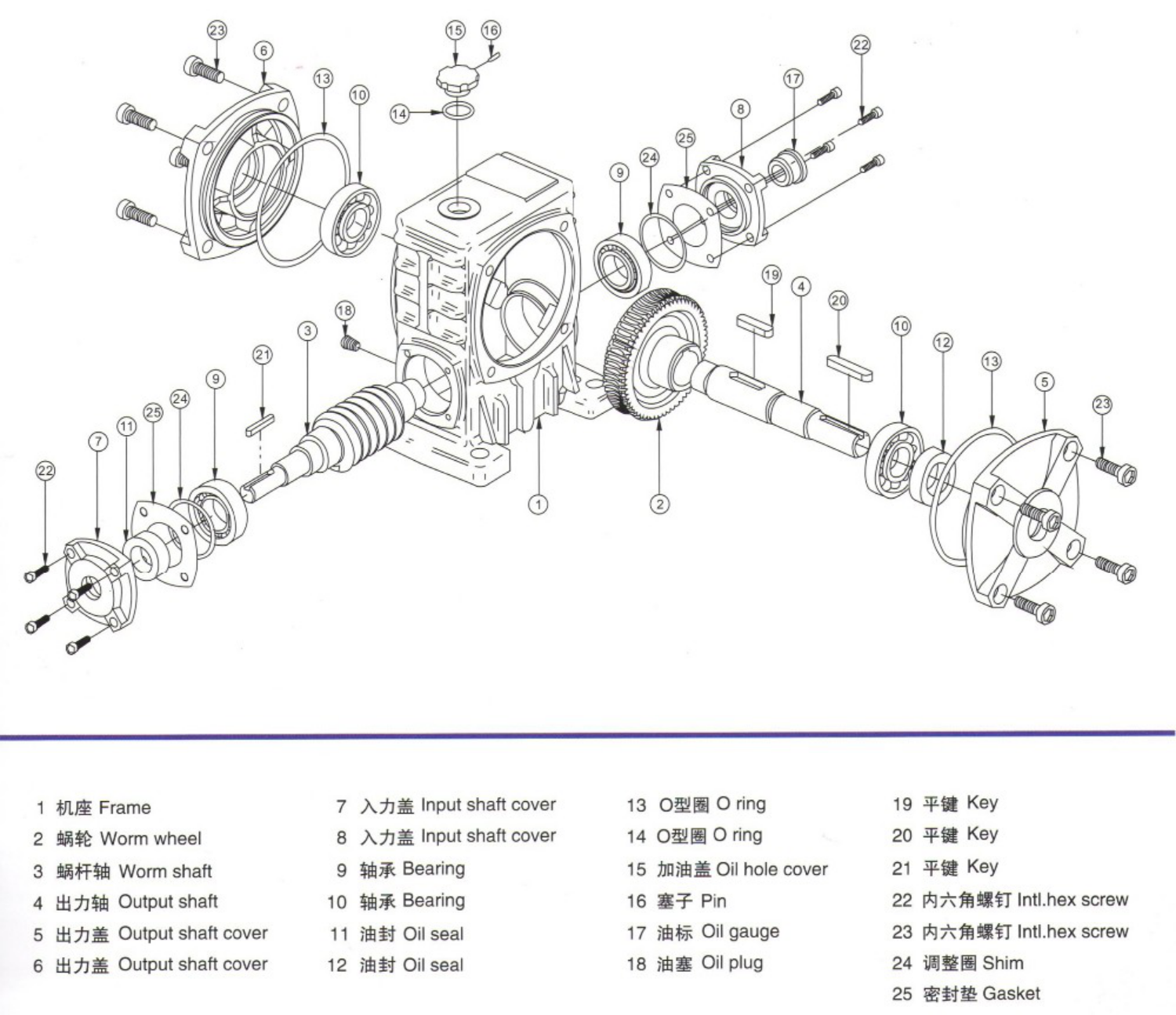

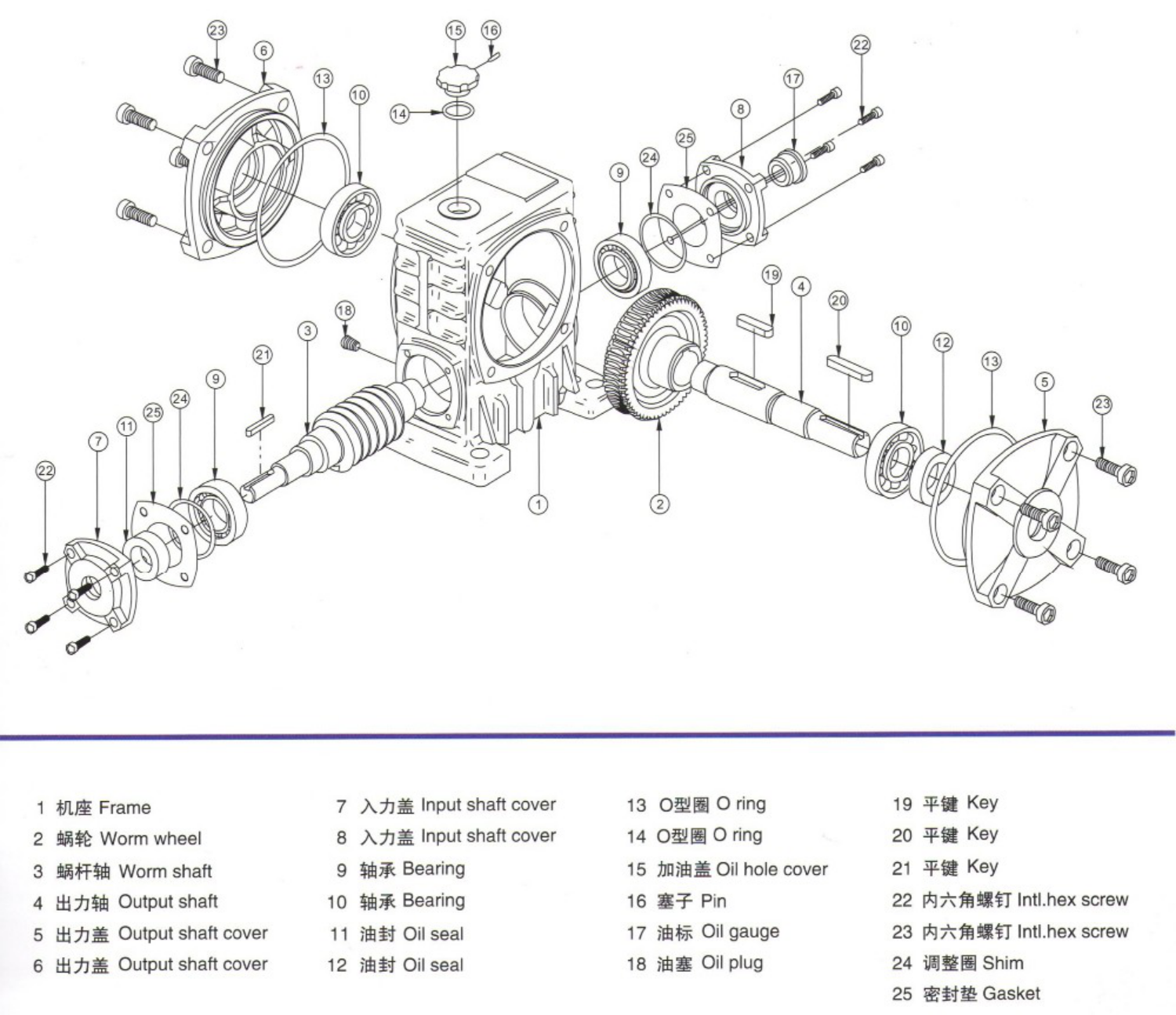

Best China manufacturer & factory China in Sialkot Pakistan Gear Reducer Small Worm Gearbox With high quality best price

If you need any information or samples, you should contact us and you will have our quickly reply.

Overview

Quick Information

- Relevant Industries:

-

Building Content Retailers, Production Plant, Machinery Restore Stores

- Gearing Arrangement:

-

Worm

- Output Torque:

-

2.6-1195N.m

- Input Pace:

-

1400r/min

- Output Velocity:

-

23.3-186.7r/min

- Spot of Origin:Zhejiang, China

- Brand Identify:

-

OEM

- One direction Totally free WHEEL (RA) Single path PAWL torque limiter (SW) Disc torque limiter clutch with spring (FFT) Design Quantity:

-

NMRV

- Rated Power:

-

.06-15KW

- Product Title:

-

China Equipment Reducer Small Worm Gearbox

- Frame Content:

-

Aluminium Alloy or Forged Iron Housing

- Worm Shaft Substance:

-

Carburizing Metal, 20CrMnTi, fifty eight-62HRC

- Worm Wheel:

-

Bronze Alloy

- Bearing Model:

-

NSK, C&U

- Lubricant:

-

Synthetic or Mineral Lubrication Oil

- Certificate:

-

CE ISO9001

- Warranty:

-

12 Months

Offer Ability

- Supply Potential:

- 600000 Piece/Parts for every Month

Packaging & Delivery

- Packaging Particulars

- Standard export packing and wooden pallets packing

- Port

- Shanghai or Ningbo Port

On the internet Customization

NMRV worm gearbox reducer is a commodity with innovative EPG is specialised in design, company and revenue of agricultural equipment and farm implements, which has an impartial import and export legal rights. design and constant advancements, its main functions are created of substantial good quality aluminum alloy, mild excess weight and non-rusting, larget output toque, sleek managing and reduced noise, large radiating efficiency, excellent hunting Business plan Our commercial plan is based mostly on the service. And we realize by provider the shipping of the merchandise in the down occasions that our costumers need us. We have produced a logistic technique in our firm that enables us to deliver merchandise the very same working day of its order anytime it is produced this get ahead of eighteen:00 hrs, to this service we have known as it “EPG Categorical”.apprearance, derable services life, little quantity and ideal for all mounting positions.

|

Output Torque |

one.8-1760Nm |

|

Software |

Machinery Sector |

|

Equipment Material |

Zepgn12-2 (BS-1400 Grade-PB2) |

|

Input Speed |

900-2800RPM |

|

Output Speed |

ten-250RPM |

Associated merchandise

Company Profile

Packing & Shipping