Product Description

Stainless Steel Coupling Gear Rigid Roller Chain Fluid Tyre Grid Jaw Spider HRC Nm Motor Flange Gear Pump Rubber Spline Shaft Flexible Universal Joint Coupling

Product Description

Main products

Coupling refers to a device that connects 2 shafts or shafts and rotating parts, rotates together during the transmission of motion and power, and does not disengage under normal conditions. Sometimes it is also used as a safety device to prevent the connected parts from bearing excessive load, which plays the role of overload protection.

Couplings can be divided into rigid couplings and flexible couplings.

Rigid couplings do not have buffering property and the ability to compensate the relative displacement of 2 axes. It is required that the 2 axes be strictly aligned. However, such couplings are simple in structure, low in manufacturing cost, convenient in assembly and disassembly, and maintenance, which can ensure that the 2 axes are relatively neutral, have large transmission torque, and are widely used. Commonly used are flange coupling, sleeve coupling and jacket coupling.

Flexible coupling can also be divided into flexible coupling without elastic element and flexible coupling with elastic element. The former type only has the ability to compensate the relative displacement of 2 axes, but cannot cushion and reduce vibration. Common types include slider coupling, gear coupling, universal coupling and chain coupling; The latter type contains elastic elements. In addition to the ability to compensate the relative displacement of 2 axes, it also has the functions of buffering and vibration reduction. However, due to the strength of elastic elements, the transmitted torque is generally inferior to that of flexible couplings without elastic elements. Common types include elastic sleeve pin couplings, elastic pin couplings, quincunx couplings, tire type couplings, serpentine spring couplings, spring couplings, etc

Coupling performance

1) Mobility. The movability of the coupling refers to the ability to compensate the relative displacement of 2 rotating components. Factors such as manufacturing and installation errors between connected components, temperature changes during operation and deformation under load all put CZPT requirements for mobility. The movable performance compensates or alleviates the additional load between shafts, bearings, couplings and other components caused by the relative displacement between rotating components.

(2) Buffering. For the occasions where the load is often started or the working load changes, the coupling shall be equipped with elastic elements that play the role of cushioning and vibration reduction to protect the prime mover and the working machine from little or no damage.

(3) Safe, reliable, with sufficient strength and service life.

(4) Simple structure, easy to assemble, disassemble and maintain.

How to select the appropriate coupling type

The following items should be considered when selecting the coupling type.

1. The size and nature of the required transmission torque, the requirements for buffering and damping functions, and whether resonance may occur.

2. The relative displacement of the axes of the 2 shafts is caused by manufacturing and assembly errors, shaft load and thermal expansion deformation, and relative movement between components.

3. Permissible overall dimensions and installation methods, and necessary operating space for assembly, adjustment and maintenance. For large couplings, they should be able to be disassembled without axial movement of the shaft.

In addition, the working environment, service life, lubrication, sealing, economy and other conditions should also be considered, and a suitable coupling type should be selected by referring to the characteristics of various couplings.

If you cannot determine the type, you can contact our professional engineer

Related products

Company Profile

Our Equipments

Main production equipment:

Large lathe, surface grinder, milling machine, gear shaper, spline milling machine, horizontal broaching machine, gear hobbing machine, shaper, slotting machine, bench drilling machine, radial drilling machine, boring machine, band sawing machine, horizontal lathe, end milling machine, crankshaft grinder, CNC milling machine, casting equipment, etc.

Inspection equipment:

Dynamic balance tester, high-speed intelligent carbon and sulfur analyzer, Blochon optical hardness tester, Leeb hardness tester, magnetic yoke flaw detector, special detection, modular fixture (self-made), etc.

Machining equipments

Heat equipment

Our Factory

Application – Photos from our partner customers

Company Profile

Our leading products are mechanical transmission basic parts – couplings, mainly including universal couplings, drum gear couplings, elastic couplings and other 3 categories of more than 30 series of varieties. It is widely used in metallurgical steel rolling, wind power, hydropower, mining, engineering machinery, petrochemical, lifting, paper making, rubber, rail transit, shipbuilding and marine engineering and other industries.

Our factory takes the basic parts of national standards as the benchmark, has more than 40 years of coupling production experience, takes “scientific management, pioneering and innovation, ensuring quality and customer satisfaction” as the quality policy, and aims to continuously provide users with satisfactory products and services. The production is guided by reasonable process, and the ISO9001:2015 quality management system standard is strictly implemented. We adhere to the principle of continuous improvement and innovation of coupling products. In recent years, it has successfully developed 10 national patent products such as SWF cross shaft universal coupling, among which the double cross shaft universal joint has won the national invention patent, SWF cross shaft universal coupling has won the new product award of China’s general mechanical parts coupling industry and the ZHangZhoug Province new product science and technology project.

Our factory has strong technical force, excellent process equipment, complete professional production equipment, perfect detection means, excellent after-sales service, various products and complete specifications. At the same time, we can provide the design and manufacturing of special non-standard products according to the needs of users. Our products sell well at home and abroad, and are trusted by the majority of users. We sincerely welcome friends from all walks of life at home and abroad to visit and negotiate for common development.p

Could you provide examples of industries or applications where spider couplings are commonly used?

Spider couplings find application in a wide range of industries and mechanical systems where torque transmission, misalignment compensation, and vibration dampening are important. Here are some examples of industries and applications where spider couplings are commonly used:

- Manufacturing: Spider couplings are used in various manufacturing equipment, including conveyor systems, packaging machinery, and CNC machines. They help transmit torque between motors and shafts while accommodating misalignment.

- Agriculture: Agricultural equipment such as tractors, combines, and harvesters often use spider couplings to connect and transmit power between different components.

- Automotive: Spider couplings can be found in automotive applications, including drive shaft connections and steering systems, where they help transfer torque and accommodate movement.

- Pumps and Compressors: Spider couplings are used in pumps and compressors to connect motors to impellers or rotors, ensuring efficient torque transmission and vibration isolation.

- Material Handling: Material handling systems, including conveyors, elevators, and cranes, use spider couplings to connect various components and transfer torque.

- Printing and Packaging: Spider couplings are used in printing presses, packaging machines, and labeling systems to ensure precise torque transmission and compensate for misalignment.

- Textile Machinery: Textile manufacturing equipment such as spinning machines and looms utilize spider couplings to connect drive components and transmit power efficiently.

- Food and Beverage: Spider couplings are used in food processing equipment and beverage production lines, where they provide sanitary and reliable torque transmission.

These examples illustrate the versatility of spider couplings in various industries and applications. Their ability to handle torque transmission, misalignment compensation, and vibration reduction makes them a practical choice for a wide range of mechanical systems.

What are the best practices for ensuring proper lubrication of spider couplings?

Proper lubrication is essential for maintaining the performance and lifespan of spider couplings. Here are some best practices to ensure proper lubrication:

- Use the Right Lubricant: Select a lubricant that is recommended by the coupling manufacturer. The lubricant should be compatible with the elastomeric spider material and the operating conditions of the machinery.

- Follow Manufacturer’s Guidelines: Adhere to the lubrication schedule and guidelines provided by the manufacturer. They will specify the appropriate lubrication intervals and the quantity of lubricant to be applied.

- Clean the Components: Before applying lubricant, make sure the coupling components are clean and free of dirt, debris, and old lubricant residues. Cleaning the components prevents contamination of the new lubricant.

- Apply Lubricant Evenly: Apply the lubricant evenly on all contact surfaces of the elastomeric spider and the coupling hub. Avoid over-lubrication, which can lead to excess buildup and potential slippage.

- Use Lubrication Tools: Some couplings may have lubrication ports or fittings that facilitate the application of lubricant. If such features are present, use the appropriate lubrication tools to ensure thorough coverage.

- Operate Coupling After Lubrication: After applying lubricant, operate the coupling for a short period to ensure that the lubricant is evenly distributed across the contact surfaces. This helps in preventing dry spots and optimizing lubrication effectiveness.

- Monitor Lubricant Condition: Regularly inspect the condition of the lubricant during routine maintenance checks. If you notice signs of contamination, degradation, or insufficient lubrication, take corrective actions promptly.

- Consider Operating Conditions: Environmental factors such as temperature, humidity, and exposure to chemicals can affect the performance of lubricants. Choose a lubricant that can withstand the specific operating conditions of the machinery.

- Document Lubrication Activities: Keep a record of lubrication activities, including the type of lubricant used, lubrication intervals, and the results of lubrication checks. This documentation helps track the history of lubrication and informs future maintenance decisions.

By following these best practices for lubrication, you can ensure that the elastomeric spider remains properly lubricated, reducing friction, wear, and the potential for premature coupling failure.

What are the advantages of using a spider coupling in industrial applications?

Spider couplings offer several advantages that make them a popular choice for various industrial applications. Here are the key advantages:

- Misalignment Compensation: Spider couplings can accommodate angular, axial, and parallel misalignments between connected shafts. This ability to compensate for misalignment reduces stress on components and extends equipment lifespan.

- Flexibility: The elastomeric spider provides flexibility that allows for slight movements between the shafts. This flexibility helps prevent excessive wear, reduces vibration transmission, and minimizes the risk of component failure.

- Vibration Dampening: The elastomeric material of the spider acts as a shock absorber, dampening vibrations generated by rotating machinery. This can lead to improved equipment performance, reduced noise, and enhanced operator comfort.

- Easy Installation: Spider couplings have a simple design with minimal components, making them easy to install and replace. Their design eliminates the need for precise alignment during installation, saving time and effort.

- Torque Transmission: Spider couplings efficiently transmit torque from one shaft to another, ensuring that power is effectively transferred between connected components.

- Minimal Maintenance: Spider couplings require minimal maintenance due to their self-lubricating and wear-resistant elastomeric material. This reduces downtime and maintenance costs for industrial machinery.

- Compact Design: Spider couplings have a compact and lightweight design, making them suitable for applications where space is limited. Their small size allows for easy integration into various systems.

- Cost-Effective: Spider couplings are relatively inexpensive compared to other coupling types, making them a cost-effective solution for a wide range of industrial applications.

- Electric Insulation: In applications where electrical isolation is important, spider couplings made from electrically insulating materials can prevent the transmission of electrical currents between shafts.

- Wide Range of Sizes: Spider couplings are available in various sizes and configurations to accommodate different shaft diameters and torque requirements.

Due to these advantages, spider couplings are commonly used in industries such as manufacturing, automation, packaging, material handling, and more, where flexibility, misalignment compensation, and efficient torque transmission are essential for optimal equipment performance.

editor by CX 2023-09-13

China Hot selling Auto Parts Aluminum Metal Universal Joint CZPT Precision CZPT Steering Gear Universal Joint CZPT CZPT for U Joint Best Sales

Solution Description

Industrial Adaptable Needle Roller Bearing Swivel Ball CZPT Steering Travel Shaft CZPT Conclude Yoke Spider Common Joint for Auto Hefty Truck Autos Spare Elements

Common joint bearing is a sort of mechanical construction which uses ball link to comprehend electricity transmission of various shafts. It is a really essential portion of bearing. The blend of universal joint and transmission shaft is known as common joint transmission gadget. The common joint CZPT bearing sold in our shop is made of specific steel, with higher strength and toughness, warmth quenching remedy, tremendous large hardness, prolonged

service life, resilient and sturdy.

Goods Description

| Title | Universal Joint/U Joint |

| Characteristics | Materials: 20Cr/steel |

| Dimensions: 22.06*fifty seven.50mm | |

| Accessaries | Snap Rings: 4pcs |

| Grease Nipples: 1pc | |

| Packing Specifics | Plastic Bags |

| White or Colour Individal Bins | |

| Carton Packing containers | |

| MOQ | 300pcs |

| Guarantee | 12 months |

| Payment | T/T, L/C, Western Union, Paypal, M1y Gram |

Business Profile

Chain couplings require periodic lubrication, relying on the software. Lubrication is typically brushed onto the chain, and caps are utilized to support keep the coupling lubricated.

Jaw Coupling A jaw coupling is a material elastic coupling that transmits torque by compressing a resilient star-shaped insert put between two intermeshing jaws. Versatile elements are generally created of NBR, Polyurethane, Hytrel, or Bronze Torque for general function purposes

China best 3j – 11j Gear Rubber Coupling, Polyurethane Coupling, PU CZPT Spider, PU CZPT Element high quality

Product Description

3j – 11j Equipment Rubber Coupling, Polyurethane Coupling, PU CZPT Spider, PU CZPT Component

Attributes:

one. Couplings for Air Compressors

2. Serious Creation Lines

three. Prime top quality with reasonable price

four. Personlized package

five. OEM supplied,A&V Checked

Claw variety surface area to area design, has the function of safeguarding, vibration and shock can create efficient damping and minimize the running in process. Claw sort teeth 2 sleeve are offset in the circumferential course, in the gap in a quincunx elastic human body of involute. When little deviations in the installation, the elastic physique avoids the tension focus. Can effectively compensate the axial, radial and angular displacement. Column pin CZPT elastomer aged-fashi1d sort of big volume, shear influence, easy to hurt, whilst the elastic physique new claw sort couplings only below the extrusion stress, so it can stand up to increased load, better put on resistance, more time provider life. And equally the amount of installation, and can be mounted vertical.

Attributes of CJ sequence CZPT products:

one has the benefits of simple construction, steady performance, secure operation

two 3 comp1nt construction, easy set up and main10ance.

3 hub and elastic human body, a selection of supplies to select from, to make sure that all can work stably in various environments.

four employing a area matching claw sort shaft hub and involute arc elasticity, can steer clear of the stress focus, the efficient transmission of higher torque, a lot more resistant to abrasion, more time service existence.

A little protuberance pad 5 elastic entire body, can isolate the metallic shaft hub contact in CZPT installed, powerful insulation, no require of lubrication. CZPT of deviation of the remedy is deformation takes place via the elastic drive at the complete.

Bodily character: made by injection with substantial top quality polyester or CZPT CSM/SBR. It is developing and special for all types of steel shaft CZPT with really excellent efficiency of higher 10sile energy, high wear resistant, higher elastic resilience, water resistant, oil resistant and excellent tiredness resilience, high impact resistant and so on. We have complete sets moulds and supply total range of GR, GS, MT, Hb, HRC, L, NM and Equipment J sequence couplings with large quality and exceptional expertise. Use to all sorts of industrial steel shaft coupling.

Specs:

materials: polyester, CSM/SBR

shade: yellow, purple, purple, environmentally friendly, black etc.

surface: smooth

10sile power: 12-55Mpa

hardness: eighty-98Shore A

elongation: four hundred%-650%

density: 1.25g/cm3

elasticity effect: >25%

tear power: 35-155KN/m

akron abrasion decline: <0.05cm3/1.61km

compression established (22h*70oC): <10%

operating temperature: 120oC

regular measurement for polyurethane coupling:

GR14, GR19, GR24, GR28, GR38, GR42, GR48, GR55, GR65, GR75, GR90, GR100, GR110, GR125, GR140, GR160, GR180

MT1, MT2, MT3, MT4, MT5, MT6, MT7, MT8, MT9, MT10, MT11, MT12, MT13

HRC70, HRC90, HRC110, HRC130, HRC150, HRC180, HRC230, HRC280

L35, L50, L70, L75, L90/ninety five, L99/100, L110, L150, L190, L225, L276

FALK-R 10R, 20R, 30R, 40R, 50R, 60R, 70R, 80R

common measurement for rubber coupling:

Hb80, Hb95, Hb110, Hb125, Hb140, Hb160, Hb180, Hb200, Hb240, Hb280, Hb315

HRC70, HRC90, HRC110, HRC130, HRC150, HRC180, HRC230, HRC280

L35, L50, L70, L75, L90/ninety five, L99/100, L110, L150, L190, L225

NM50, NM67, NM82, NM97, NM112, NM128, NM148, NM168, NM194, NM214, NM240, NM265

Equipment 3J, 4J, 5J, 6J, 7J, 8J, 9J, 10J, 11J

unique dimensions create molding according to the buyer’s drawings

***when you enquiry, pls validate product’s quantity and quantity***

Couplings fall into two wide categories: substance bending and mechanical bending. Flexible content sorts obtain overall flexibility by stretching or compressing elastic components this sort of as rubber or bending thin steel discs or meshes. Material elastic couplings do not require lubrication, besides for mesh couplings. Mechanical flex couplings accept misalignment triggered by wobbling, rolling, or sliding of metallic surfaces. All steel mechanical adaptable couplings demand lubrication.

Consisting of two radially slotted hubs and a serpentine spring metal band, the mesh coupling supplies the torsional damping and flexibility of an elastomer, but with the power of steel. Grid couplings transmit torque and adjust angular, parallel and axial misalignment from one hub to yet another by oscillating and sliding a tapered grid in the hub grooves. The mesh cross part is normally tapered for greater hub get in touch with and easier assembly. Lubrication is essential due to the motion amongst the speak to hub and the mesh metallic parts.

China best HRC Couplings Stainless Steel Spider CZPT Shaft Flexible Rubber Alloy Chains Gear Connectors High Pressure Camlock Non-Lovejoy Shear Pin Beam Disc Jaw Clamp factory

Item Description

Merchandise Description

Quick Depth:

HRC Couplings

Double cardanic variety DKM Coupling

C45 metal, Alloy steel, Aluminum and so forth. content

Regular and non-standard CZPT available

With high top quality and aggressive price

Prompt delivery

Packing as per customer’s desire.

Description:

We are the top best Chinese CZPT maker, and are specializing in various substantial top quality Double cardanic kind DKM

Coupling.

one. For higher shaft displacements

two. 3-part double-cardanic

3. Reduced vibration and sound

four. The restoring forces ensuing from displacements are quite minimal

5. Enhance of the overall lifetime of all adjacent comp1nts (bearings,seals and so on.)

six. Approved in accordance to EC Common 94/9/EC(Explosion Certificate ATEX 95)

7. Double-cardanic layout CZPT the require for bearing assistance or exterior guarding

8. Complete bore in accordance to ISO fit H7, feather keyway according to DIN 6885 (JS9)

9. Dimension: 19, 24, 28, 38, forty two, forty eight, 55, 65, seventy five, 90 mm

Purposes:

HRC Couplings Double cardanic kind DKM CZPT are supplied in the industry’s biggest variety of inventory bore/keyway combinations.

These couplings need no lubrication and offer highly trustworthy support for light, medium, and weighty obligation electrical motor and

interior combustion electrical power transmission apps. Applications include power transmission to industrial products this sort of as

pumps, equipment packing containers, compressors, blowers, mixers, and conveyors.

Advisable Items

FAQ

Q: Are you buying and selling company or producer ?

A: Our group consists in 3 factories and 2 abroad product sales firms.

Q: Do you offer samples ? is it totally free or further ?

A: Of course, we could offer you the sample for cost-free cost but do not pay the cost of fr8.

Q:How extended is your shipping and delivery time ? What is your terms of payment ?

A: Generally it is 40-45 times. The time may possibly differ depending on the item and the amount of customization. For standard products, the payment is: 30% T/T in CZPT ,equilibrium ahead of shippment.

Q:What is the actual MOQ or value for your solution ?

A: As an OEM organization, we can provide and adapt our products to a broad assortment of needs.As a result, MOQ and value might drastically range with dimensions, content and even more technical specs For occasion, expensive merchandise or standard products will usually have a lower MOQ. You should contact us with all appropriate information to get the most precise quotation.

If you have an additional query, make sure you really feel cost-free to speak to us.

Why Decide on Us

Also I would like to just take this opportunity to give a brief introduction of our Ever-Electrical power organization: Our business is a famous

maker of agriculture gearbox,worm reduce gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in

china. We have exported many products to our consumers all more than the planet, we have prolonged-time encounter and sturdy engineering

help. Some of our client : Italy: GB GEABOX, SATI, CHIARAVALLI, AMA, CZPT Germany: SILOKING ,GKN ,KTS France: Itfran,

Sedies, Kuhn Brazil: AEMCO ,STU United states: John Deere , BLOUNT, Weasler, Agco, CZPT Gear, OODSCanada:JAY-LOR , CANIMEX ,RingBall

…… -> Our Firm with in excess of twelve year’s history and one thousand employees and 20 income. -> With more than a hundred Million USD revenue in 2017 ->

With CZPT machinery equipments -> With big work potential and substantial good quality handle, ISO certified. …… you also can verify

our site to know for a lot more information, if you want our merchandise catalogue, you should get in touch with with us.

Speak to Us

Diaphragm Couplings Diaphragm couplings use a one or a series of plates or diaphragms as flexible aspects. It transfers torque from the outer diameter of the flex plate to the internal diameter, through the spool or spacer, and then from the inner diameter to the outer diameter. When the diaphragm is subjected to misalignment, the outer diameter is deflected relative to the inner diameter. For instance, axial displacement attempts to extend the diaphragm, which benefits in a mix of elongation and bending of the diaphragm profile. Angular, parallel and high axial misalignment permitted Best for large torque, high pace programs

Consisting of two radially slotted hubs and a serpentine spring metal band, the mesh coupling offers the torsional damping and versatility of an elastomer, but with the toughness of metal. Grid couplings transmit torque and change for angular, parallel and axial misalignment from one hub to the other by oscillating and sliding tapered grids in the hub grooves. The mesh cross area is normally tapered for much better hub contact and less difficult assembly. Lubrication is needed thanks to the movement in between the make contact with hub and the mesh metallic components.

China high quality Gear Rubber Coupling, Hypalon Gear Coupling, Rubber Gear Coupling Made with DuPont Hypalon Best Sales

Item Description

Gear Rubber Coupling, Hypalon Gear Coupling, Rubber Equipment CZPT Created with DuPont Hypalon

Functions:

one. Couplings for Air Compressors

2. Significant Production Lines

three. Best good quality with affordable price tag

four. Personlized bundle

five. OEM supplied,A&V Checked

Claw sort floor to floor style, has the perform of protecting, vibration and shock can produce powerful damping and minimize the managing in procedure. Claw sort teeth two sleeve are offset in the circumferential direction, in the hole in a quincunx elastic physique of involute. When little deviations in the set up, the elastic body avoids the stress focus. Can properly compensate the axial, radial and angular displacement. Column pin coupling elastomer aged-fashioned kind of huge volume, shear impact, straightforward to harm, although the elastic body new claw type couplings only under the extrusion stress, so it can endure better load, better dress in resistance, longer support existence. And the two the degree of set up, and can be set up vertical.

Attributes of CJ series coupling merchandise:

one has the advantages of straightforward framework, stable functionality, steady operation

two three component structure, straightforward installation and upkeep.

three hub and elastic body, a range of materials to decide on from, to guarantee that all can work stably in different environments.

four utilizing a floor matching claw type shaft hub and involute arc elasticity, can keep away from the tension focus, the efficient transmission of higher torque, far more resistant to abrasion, for a longer time services existence.

A tiny protuberance pad 5 elastic physique, can isolate the metallic shaft hub get in touch with in coupling set up, successful insulation, no want of lubrication. CZPT of deviation of the solution is deformation occurs via the elastic pressure at the finish.

Physical character: produced by injection with higher high quality polyester or mould CSM/SBR. It is developing and specific for all varieties of steel shaft coupling with extremely great efficiency of high tensile strength, high dress in resistant, large elastic resilience, water resistant, oil resistant and exceptional tiredness resilience, higher influence resistant and so on. We have full sets moulds and provide total range of GR, GS, MT, Hb, HRC, L, NM and Gear J series couplings with high top quality and superb experience. Utilize to all types of industrial metallic shaft coupling.

Technical specs:

substance: polyester, CSM/SBR

shade: yellow, red, purple, environmentally friendly, black etc.

floor: easy

tensile energy: 12-55Mpa

hardness: 80-98Shore A

elongation: 400%-650%

density: 1.25g/cm3

elasticity impact: >25%

tear strength: 35-155KN/m

akron abrasion decline: <0.05cm3/1.61km

compression established (22h*70oC): <10%

functioning temperature: 120oC

normal size for polyurethane coupling:

GR14, GR19, GR24, GR28, GR38, GR42, GR48, GR55, GR65, GR75, GR90, GR100, GR110, GR125, GR140, GR160, GR180

MT1, MT2, MT3, MT4, MT5, MT6, MT7, MT8, MT9, MT10, MT11, MT12, MT13

HRC70, HRC90, HRC110, HRC130, HRC150, HRC180, HRC230, HRC280

L35, L50, L70, L75, L90/ninety five, L99/one hundred, L110, L150, L190, L225, L276

FALK-R 10R, 20R, 30R, 40R, 50R, 60R, 70R, 80R

regular measurement for rubber coupling:

Hb80, Hb95, Hb110, Hb125, Hb140, Hb160, Hb180, Hb200, Hb240, Hb280, Hb315

HRC70, HRC90, HRC110, HRC130, HRC150, HRC180, HRC230, HRC280

L35, L50, L70, L75, L90/ninety five, L99/one hundred, L110, L150, L190, L225

NM50, NM67, NM82, NM97, NM112, NM128, NM148, NM168, NM194, NM214, NM240, NM265

Equipment 3J, 4J, 5J, 6J, 7J, 8J, 9J, 10J, 11J

specific measurement construct molding in accordance to the buyer’s drawings

***when you enquiry, pls confirm product’s quantity and quantity***

Jaw Coupling A jaw coupling is a material elastic coupling that transmits torque by compressing a resilient star-shaped insert placed between two intermeshing jaws. Flexible aspects are normally produced of NBR, Polyurethane, Hytrel, or Bronze Torque for basic function programs

Best made in China – replacement parts – pintle Chain & sprocket manufacturer : OEM all balls racing chain roller China in Copenhagen Denmark Design Hardened Steel Motorcycle Flywheel Chain Sprocket Gear with ce certificate top quality low price

We – EPG Group the greatest Chain and agricultural gearbox manufacturing facility in China with 5 various branches. For a lot more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

Our solution range also handles locking assemblies (clamping elements/locking system), taper bushes, QD bushes, bolt-on hubs, pto shaft, agricultural gearboxes,torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, common joint, rod finishes and yokes. EPG In this way, our goods have ongoing to obtain industry acceptance and clients gratification more than the past number of a long time.energy transmission goods are created to deliver equally reliable performance and cost-effectiveness. Every single product is utility-tested and engineered to satisfy stringent specifications for uniformity in dimension, heat treatment, tensile strength and other critical attributes. As a value-successful substitute developed specifically for basic-obligation use, EPG’s expanding line of items are available in all usually purchased sizes and technical specs, such as ball bearings, mounted models, roller chain, seals, gauges, sheaves and more. EPG major manufacturer and supplier of ball bearings and electricity transmission gear. Since it’s beginning in 1992, EPG has grown into one of the leading suppliers in the business. Crucial aspects that have contributed to our development is our commitment to the fundamentals of innovative design and style, competitive pricing, excellent customer support, and item availability. Hardened steel bike flywheel chain sprocket equipment OEM value

Surface: as your requirement

Materials: steel / aluminum / brass / iron / zinc / alloy

Any other material and dimension depends on customers’ demand.

Usage: machinery / furniture / toy / woodboard / wall

Manufacturing process: Precision lathe parts

Euipment: lathe machine

Testing equipment: Projector, Hardness, Salt Spray, Roughness Tester, Height Gauge

Tolerance:+/-.05MM

| Industry Focus | Equipment/ Automotive/ Agricultural Electronics/ Industrial/ Marine Mining/ Hydraulics/ Valves Oil and Gas/ Electrical/ Construction |

| Intended Application | Shafts Valve Components Automatic Door Components Cable/ Electronic Connector Fire Suppression System Components Fittings/ Fasteners Gears/ Hardware Roller Bearings |

| Lead Times Available |

Max: 2 Weeks (On Initial Order) Rush Services Available |

| Industry StHangZhourds | ISO 9001:2008 PPAP RoHS Compliant |

| Additional Capabilities | CAD Design Services CAM Programming Services Coordinate Measuring Machines (CMM) Reverse Engineering |

| Equipment List | From simple 2-axis turning to 7-axis, turn-mill-drill CNC Swiss-type machines, we are equipped with a full line of CNC equipment from the following manufactures: molding machines/ stamping machines automatic lathe machines/ spring machines. |

| Automation Capabilities | Continuous Machining |

| Material (Metals) | Alloy Steels/ Aluminum/ Brass/ Bronze Alloys Carbon Steel/ Copper/ Stainless Steel/ Tool Steel Cold Rolled Steel/ Bearing Steel |

| Material (Plastic Polymers) |

Ab muscles/ Delrin/ Nylon/ PVC |

| Procedures (Special Capabilities) |

Broaching/ Hobbing/ Slotting |

| Tolerance | ±0.0002 in ±0.0051 mm |

FAQ

Q1:How to guarantee the Quality of Industrial Parts?

A1:we are ISO 9001-2008 certified firm. we have the integrated system for industrial parts quality control. We have IQC (incoming quality control), IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2:What’s the Advantage of Your Parts for Industry Products?

A2:Our advantage is the competitive prices, fast delivery and high quality. Our employees are responsible-oriented, friendly-oriented,and dilient-oriented. our Industrial parts products are featured by strict tolerance, smooth finish and long-life performance.

Q3:what are our machining equipmengts?

A3:Our machining equipments include CNC milling machines, CNC turning machines, stamping

machines,hobbing machines, automatic lathe machines, tapping machines, grinding machines,

screw machines, cutting machines and so on.

This fall: What shipping ways our use?

A4:Generally speaking, we will use UPS or DHL to ship the products. Our customers can reach the

products within 3 days.If our customers do not need them urgently, we will also use Fedex and TNT.If the products are of heavy weight and large volumn, we will ship them by sea. This way can save

our customers a lot of money.

Q5:Who are our main customers?

A5:HP, Samsung, Jabil Group,Lexmark,Flextronic Group.

Q6:What materials can you handle?

A6:Brass,bronze,copper,stainless steel, steel,aluminum,titanium And plastic.

Q7:How Long is the Delivery for Your Industrial Part?

A7:Generally speaking, it will take us 15 working days for machining parts and 25 working days for

the for stamping parts products. But we will shorten our lead time according to customers’ demands

if we are able to.

The use of authentic products manufacturer’s (OEM) portion numbers or emblems , e.g. CASE® and John Deere® are for reference purposes only and for indicating solution use and compatibility. Our company and the detailed substitute elements contained herein are not sponsored, authorized, or produced by the OEM.

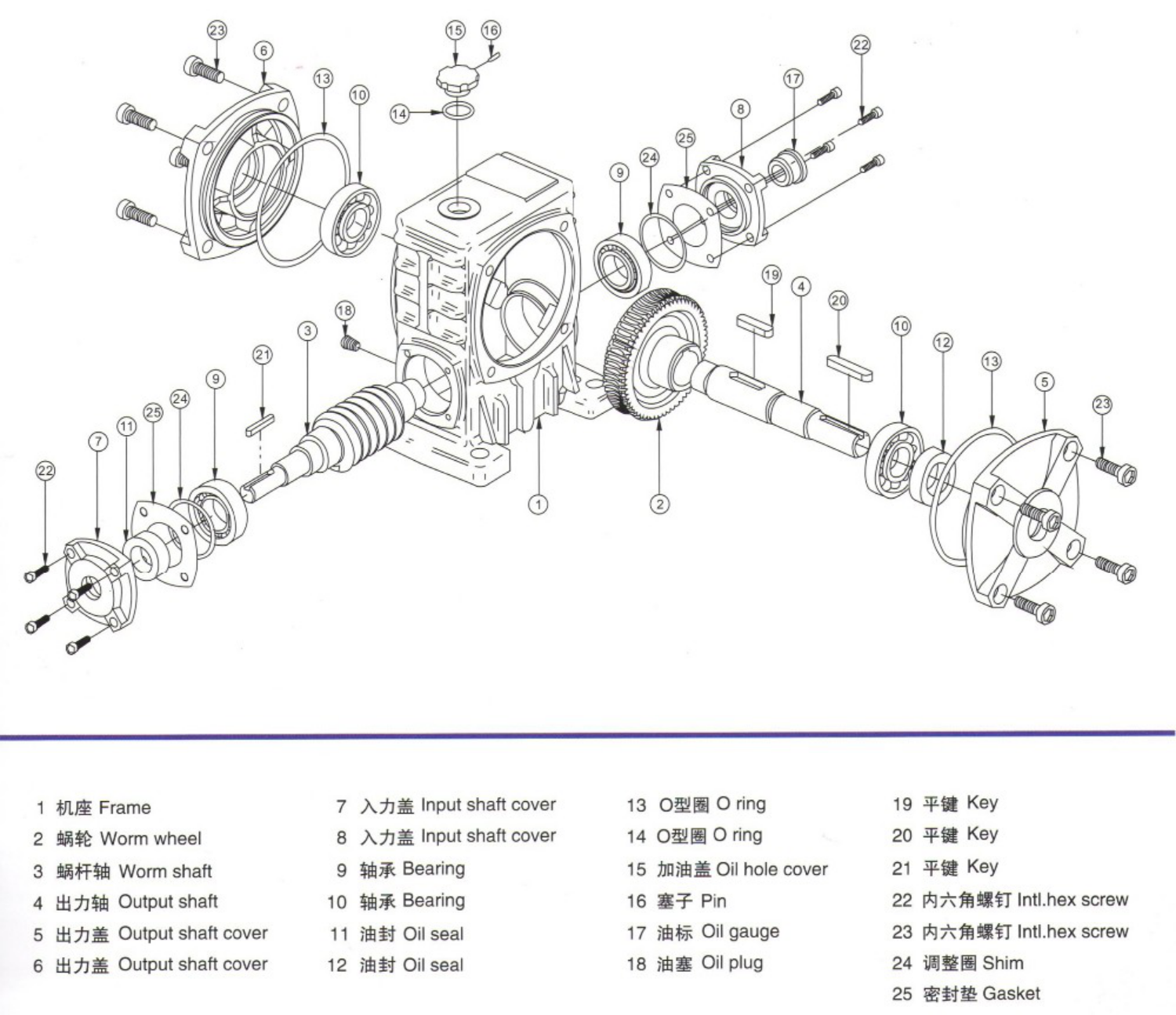

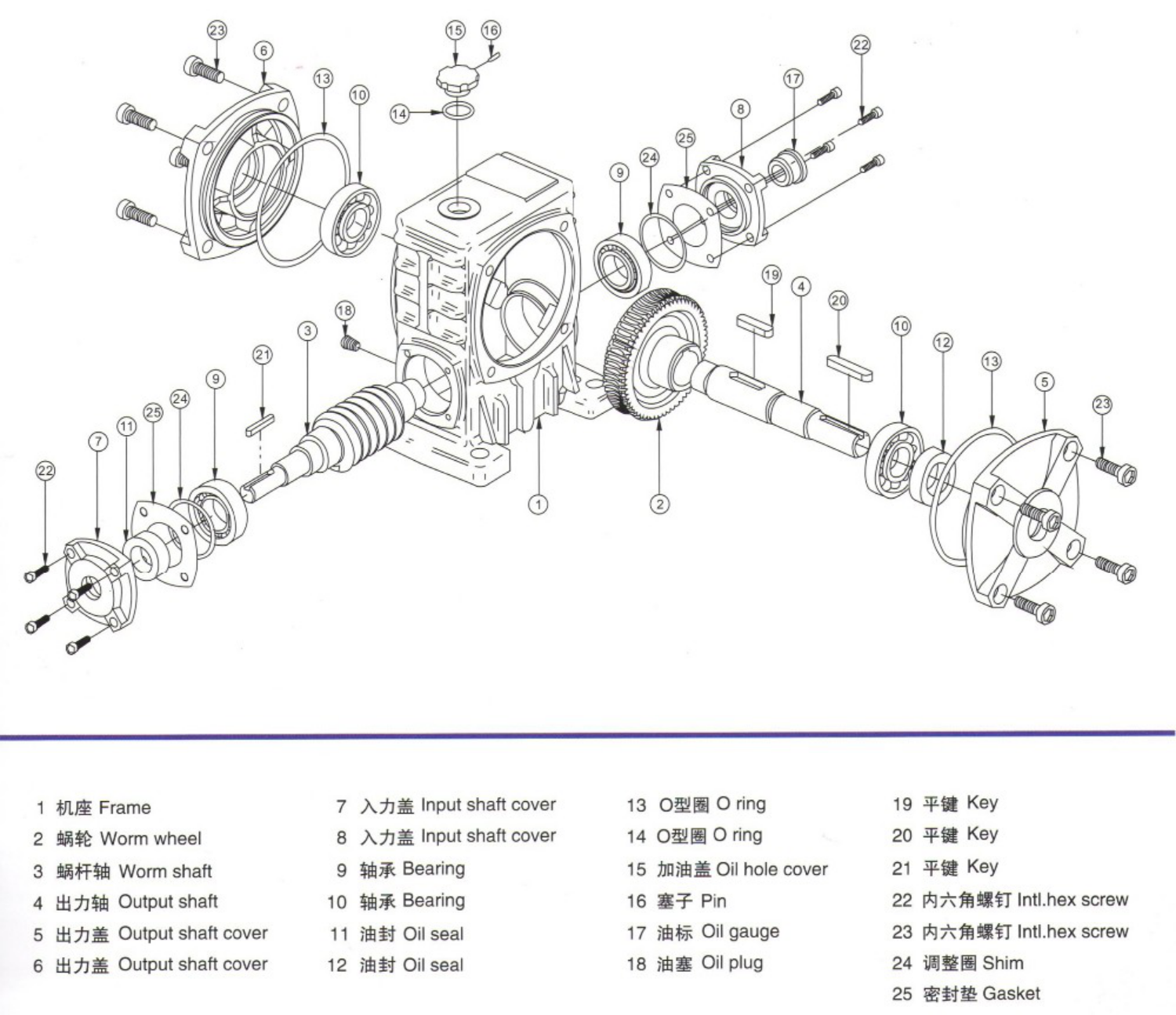

Best China manufacturer & factory China in Sialkot Pakistan Gear Reducer Small Worm Gearbox With high quality best price

If you need any information or samples, you should contact us and you will have our quickly reply.

Overview

Quick Information

- Relevant Industries:

-

Building Content Retailers, Production Plant, Machinery Restore Stores

- Gearing Arrangement:

-

Worm

- Output Torque:

-

2.6-1195N.m

- Input Pace:

-

1400r/min

- Output Velocity:

-

23.3-186.7r/min

- Spot of Origin:Zhejiang, China

- Brand Identify:

-

OEM

- One direction Totally free WHEEL (RA) Single path PAWL torque limiter (SW) Disc torque limiter clutch with spring (FFT) Design Quantity:

-

NMRV

- Rated Power:

-

.06-15KW

- Product Title:

-

China Equipment Reducer Small Worm Gearbox

- Frame Content:

-

Aluminium Alloy or Forged Iron Housing

- Worm Shaft Substance:

-

Carburizing Metal, 20CrMnTi, fifty eight-62HRC

- Worm Wheel:

-

Bronze Alloy

- Bearing Model:

-

NSK, C&U

- Lubricant:

-

Synthetic or Mineral Lubrication Oil

- Certificate:

-

CE ISO9001

- Warranty:

-

12 Months

Offer Ability

- Supply Potential:

- 600000 Piece/Parts for every Month

Packaging & Delivery

- Packaging Particulars

- Standard export packing and wooden pallets packing

- Port

- Shanghai or Ningbo Port

On the internet Customization

NMRV worm gearbox reducer is a commodity with innovative EPG is specialised in design, company and revenue of agricultural equipment and farm implements, which has an impartial import and export legal rights. design and constant advancements, its main functions are created of substantial good quality aluminum alloy, mild excess weight and non-rusting, larget output toque, sleek managing and reduced noise, large radiating efficiency, excellent hunting Business plan Our commercial plan is based mostly on the service. And we realize by provider the shipping of the merchandise in the down occasions that our costumers need us. We have produced a logistic technique in our firm that enables us to deliver merchandise the very same working day of its order anytime it is produced this get ahead of eighteen:00 hrs, to this service we have known as it “EPG Categorical”.apprearance, derable services life, little quantity and ideal for all mounting positions.

|

Output Torque |

one.8-1760Nm |

|

Software |

Machinery Sector |

|

Equipment Material |

Zepgn12-2 (BS-1400 Grade-PB2) |

|

Input Speed |

900-2800RPM |

|

Output Speed |

ten-250RPM |

Associated merchandise

Company Profile

Packing & Shipping

Best China manufacturer & factory factory in Mbeya United Republic of Tanzania manufacturer for High quality cog gear china supplier cnc machining spiral bevel With high quality best price

ensures the steadiness and consistency of the important perform of elements.

Overview

Swift Details

- Applicable Industries:

-

Manufacturing Plant

- Item Key phrases:

-

cog equipment,china supplier cnc machining gear,china spiral bevel gear

Supply Capacity

- Provide Capability:

- 5000 Piece/Parts for each Month

Packaging & Supply

- Packaging Specifics

- Neutral paper packaging, wood packing containers for outer box or in accordance to customer’s need.

- Port

- Shanghai Port / Ningbo Port

On the internet Customization

The company masking 88,000 sq. meters, has advanced products and sturdy specialized toughness, this sort of as the numerical handle machine tools and machining facilities, CAD/CAM technique, inThe EPG Group range of PTO shafts add-ons includes various sorts of yokes for the link of the tractor electrical power consider-off with recessed push button and/or ball collar and/or ball collar for continuous velocity joints, with the pursuing spline proportions: 1”3/8 Z6 – 1”3/8 Z6 -1”3/8 Z21- 1”3/4 Z6- 1”3/4 Z20dustrial robot etc.

Machining of the gearbox To make a worm gearbox, first consider a blank of an alloy. A bronze bearing is manufactured in the middle of the blank. The hobbing cutter is then utilized to minimize the diameter of the blank relative to the finished top of the tooth tip on the equipment wheel, so the depth of the cut wants to be additional to the blank’s diameter. The required threading device is grind to minimize the worm. The aspect clearance on the left-hand side of the cutter tip is permitted for the worm’s pitch angle. The ideal complete is place on the chopping resource making use of a slip stone. Equipment blank is then mounted on a turntable that acts as a bearing support. This bearing assist is mounted on the rear of the lathe cross-slide with the hobbing cutter mounted between the facilities. The two worms are then machined, out of which a single is made the cutter and lastly the cutter is used to equipment the worm gear.

We Ever-Energy Group with 4 branches above 1200 staff is one particular of the greatest transmission areas and machining products companies in China

Product Description

Merchandise Description:

We specialized in producing automobile gears , motorbike gears, gearbox, unique automobile (electrical power takeoff, snowmobiles, engineering cars) gears, generator equipment, stainless steel ice crusher and so forth.

|

Substance |

1020,1045,20CrMnTi, and many others. |

|

Machining Process |

Equipment Hobbing , Gear Shaping, Equipment Shaving, Equipment Grinding |

|

Modules |

1., 1.25, 1.5, 1.75, 2., 2.twenty five, 2.5….8. and many others. |

|

Heat Treatment method |

Carburizing & Quenching, Carbonitriding |

|

Regular |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |